Rice

Who we are?

Rice is the seed of the monocot plants Oryza sativa (Asian rice) or Oryza glaberrima (African rice). As a cereal grain, it is the most important staple food for a large part of the world's human population, especially in Asia and the West Indies. Unmilled rice, known as paddy (Indonesia and Malaysia: padi; Philippines, palay), is usually harvested when the grains have a moisture content of around 25 percent. In most Asian countries, where rice is almost entirely the product of smallholder agriculture, harvesting is carried out manually, although there is a growing interest in mechanical harvesting.

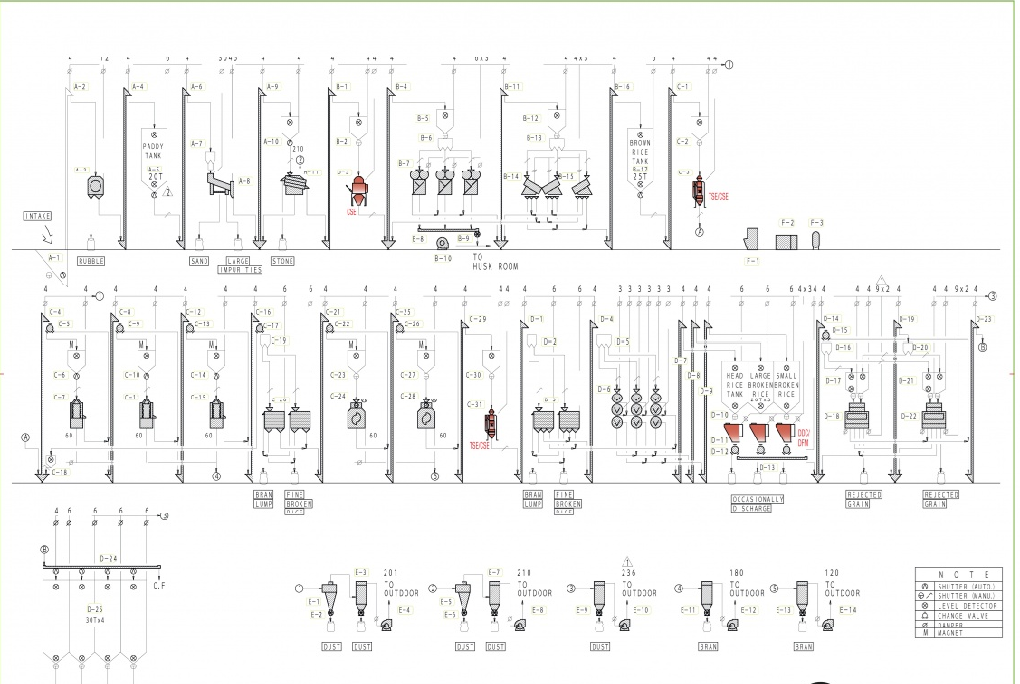

Harvesting can be carried out by the farmers themselves, but is also frequently done by seasonal labour groups. Harvesting is followed by threshing, either immediately or within a day or two. Again, much threshing is still carried out by hand but there is an increasing use of mechanical threshers. Subsequently, paddy needs to be dried to bring down the moisture content to no more than 20 percent for milling. A familiar sight in several Asian countries is paddy laid out to dry along roads. However, in most countries the bulk of drying of marketed paddy takes place in mills, with village-level drying being used for paddy to be consumed by farm families. Mills either sun dry or use mechanical driers or both. Drying has to be carried out quickly to avoid the formation of moulds. Mills range from simple hullers, with a throughput of a couple of tons a day, that simply remove the outer husk, to achieve a paddy-to-rice conversion rate of up to 72 percent but smaller, inefficient mills often struggle to achieve 60 percent. These smaller mills often do not buy paddy and sell rice but only service farmers who want to mill their paddy for their own consumption.

RICE

Our solutions:

EFRThe Electronic flow regulator, or impact device, is intended to control the outgoing flow of free-flowing granular products.

LWFThe loss in weight feeder DFM is intended to accurately measure and control the outgoing flow of free-flowing granular products.

CSEpThe CSEp is intended to measure high capacity of free flowing granular and powdery products, a typical installation could be bulk product monitoring after ship uploader or product intake monitoring in a storage silos . Thanks to our special design we do not need for surge hopper

The CSE has the same concept of the CSEp but smaller sizes, it is intended to be use for monitoring of bulk product flow. The use of 2 weighing hopper alternately feed by a diverter switch feeder allow to never stop incoming product flow.

TSE

The TSE machine is intended to measure flow of granular and floury products.

PPMWA

Suitable for average and high production rate. PPMWA is based on simplex or duplex net weight bagging scales and it is designed to handle both, granular and powder products.

PPISPPIS is suitable for both granular and powder products. His capacity is ranging from 6 to 8 bags/min. It can handle bags of different material, even the most difficult one such as woven PP bags.

CARTEL

Labels are sewn together with bag

STICKY

Automatic applicator for sticky labels. Labels are stuck on the filled bags.

NP

Heavy duty in-line check weigher for filled bags.

MD

Heavy duty in-line meteal detector for filled bags.

CLAMP TURNER

Pneumatically operated rotating clamp bag turner for inline bottom-ahead bag presentation.

STATIC TURNER

Free roller static bag turner for inline bottom-ahead bag presentation.

SPEED TURNER

High speed automatic bag turner for inline bottom-ahead bag presentation.

KICKER

Automatic bag kicker able to present filled bags 90° to the bag closing conveyor, laid-down, bottom-first.

TRUCK LOADER

Truck or wagon loading system for filled bags.

PPMWJ

Jumbo bag (FIBC) weighing filling line. Several models and options are available for production up to 80 Big Bags/hours

Button